Telemetry solutions have helped transform operations across the construction industry – and the technology is advancing quickly. Telematics for working at heights specifically ensures advanced safety, security and efficiency over your fleet. What’s more, the data can be monitored remotely, giving you greater control and flexibility.

Equipment safety is paramount, especially in the case of elevated machinery, including scissor lifts and cherry pickers. Disregarding safety protocols can lead to severe physical injuries and pose a substantial risk to brand integrity and reputation.

As telemetry technology advances, so do the features available to operators. This data gives your business greater transparency of day-to-day operations without being onsite. In this article, we explore the different types of telematics for working at heights and how to use their features to your advantage.

Choosing telematics for elevated work platforms

The first step in finding which telemetry solutions would work best for your business is to identify:

- What data do you want to report on for efficiency and productivity?

- What data do you need to report on for safety and compliance?

- What budget are you willing to invest in telematics for working at heights?

These core considerations will help you navigate the best telemetry solution for your business.

Telemetry data gives your business greater transparency of day-to-day operations without being onsite.

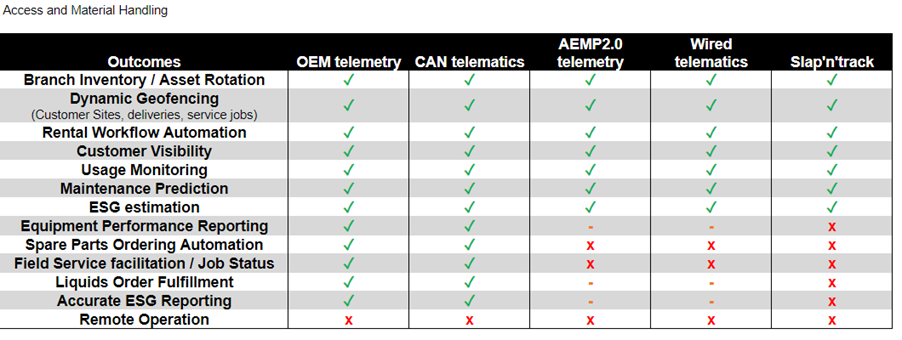

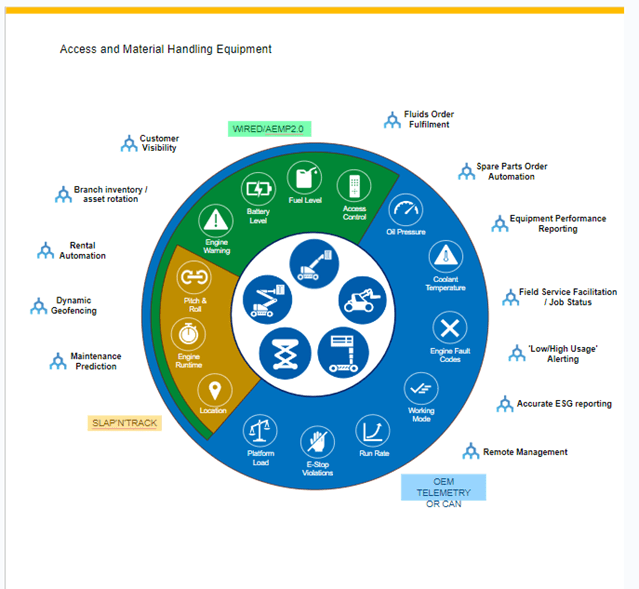

The different telemetry options for your machinery

Original Equipment Manufacturer (OEM)

OEM involves integrated telemetry solutions embedded directly within the machinery during manufacturing. Typically found in modern equipment, OEM telemetry offers a comprehensive dataset such as diagnostics and fleet management.

Controller Area Network (CAN)

Known for their compatibility across a broad range of machinery, CAN telematics are suitable for use in various equipment where a CAN signal is available. Although pricier than other solutions, they provide valuable fault codes based on mappings maintained by the telemetry provider, contributing to efficient monitoring and management of equipment health.

AEMP2.0

AEMP2.0 ensures consistency and compatibility across different types and brands of equipment. While variations exist within the AEMP2.0 framework, there are common data fields that facilitate a somewhat standardised approach to data management.

Wired Telematics

These lower-cost systems establish a direct connection by cabling into the electrical wiring of the asset. This approach not only ensures reliability but also simplifies data acquisition by offering a limited set of direct data points such as liquid levels and engine status lights.

Slap ‘n’ Track

Known for its simplicity and cost-effectiveness, Slap ‘n’ Track telemetry is a valuable solution for real-time monitoring at heights. True to its name, this solution is easily removable, providing a flexible and straightforward approach to work at height equipment tracking.

Understanding data outputs for optimal performance

It’s fair to say there’s a telemetry solution to suit all budgets and business needs. In some cases, the more you invest, the more value you’ll get from your data, but in other cases, overcomplicating the data can cause an administrative nightmare.

Max Girault, Chief Commercial Officer at Inauro, is very familiar with work at heights equipment tracking and understands the day-to-day impacts of not only sourcing the right telemetry solution but also the right data fusion platform to accurately report and manage your data.

“In some ways, it’s about making sure that you don’t bite off more than you can chew. Leveraging the complete data set from a CAN or OEM-supplied telemetry system takes a lot of work. So unless you’ve got the processes and the digital capability in the background to support it, you probably don’t need to invest that amount of money in a comprehensive solution,” advises Max.

Operational benefits of telemetry for working at heights

Max says, “Access and material handling equipment covers a broad spectrum of vehicles, from small scissor lifts to big boom lifts and knuckle booms – all at various price points. Any equipment working at height, sometimes over 80 feet above ground, immediately has a considerable safety concern. Small structures can become unstable if not operated correctly.”

“We’re also seeing more and more access and material handling equipment shift from fuel to electric, which can bring a whole set of different challenges. Workers are arriving on site and finding flat batteries, rendering machines inoperable until they can be charged, which can delay projects considerably and have a ripple effect on various contractors,” he adds.

Avoid accelerated asset depreciation with safety measures

“Assets that are not operated correctly can have accelerated depreciation,” advises Max. “The telemetry override restriction is a key safety benefit for access equipment. If people use the equipment with override on, they’re not respecting the limitations of the asset and could end up causing serious injury, as well as long-term damage to the asset’s engine and operating capacity.”

Theft is also a common concern for equipment. Max says, “The equipment can easily be taken off-site or used inappropriately, so monitoring its GPS location and usage can help companies verify any misconduct or theft.”

OEM and CAN/Modbus offer advanced telemetry for elevated safety management. They can give you greater insight into the performance of your equipment, helping to improve best practices and operational governance.

Strengthen your business model with greater visibility

Telematics for working at heights is empowering new business opportunities with the ability to control monitoring and governance. Businesses can now access control and utilisation analytics in real-time, giving you a good view of who’s using the equipment, when it’s used and what it’s used for. Operators who hire out equipment can then monitor their equipment usage to the exact minute and location from a remote computer and charge accordingly.

These abilities increase security measures, which can be restricted by key codes, to enforce restrictions to trained operators or a specific group at any given time, preventing unauthorised use.

“This gets pretty interesting when you’ve got a site with many different stakeholders and subcontractors that need the same equipment to do a job”, advises Max. “Both the rental company and the onsite operations team can have better visibility across which equipment is being utilised from each supplier and charge accordingly,” he says.

Businesses can now access control and utilisation analytics in real-time, giving you a good view of who’s using the equipment, when it’s used and what it’s used for.

Implementing telemetry solutions

Choosing the right telematics will depend on the equipment capabilities, your business needs and the level of data you require.

Considerations need to include short-term goals and future-proofing. As Max aptly puts it, “It’s about understanding what you want to achieve in a short time frame and the expected lifespan of your equipment.”

It’s time to make your data work for you

Integration and implementation, especially with platforms like Perspio™, are crucial in streamlining the transition to telemetry-driven operations. The team at Inauro are ready to help you make the most of your data and remove the complexities around telemetry solutions.

If you’re interested in hearing more about the best telematics for working at heights and material handling equipment, reach out to the Inauro team today.