IoT or Internet of Things is a term that gets used more and more frequently, both in work settings and at home. IoT is a bit like another of those wonderfully hyped technology terms “Cloud”. In the same way that you don’t buy a “Cloud” (you buy storage, network and compute hardware, management and application software that all together make a cloud solution), you don’t buy an IoT either. You buy devices, connectivity networks and then the platforms to process, analyse and visualise the data from your ‘things’, with bonus points if you can integrate this data into the way you operate.

What is IoT?

Simply put, IoT is the collection of items or ‘things’, that are connected to a platform that can then help you better operate, manage or monitor these items.

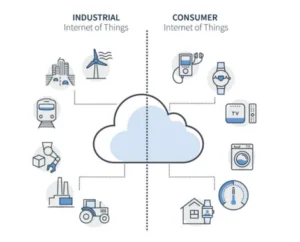

There is an important distinction to make when you are talking about IoT and that is the difference between Industrial IoT and Consumer IoT.

Industrial IoT is what your business or enterprise will use (factory machines, trucks, excavators, smart buildings etc), consumer IoT is what you use at home (fridges, TVs, smart lighting etc). There are big (and very important!) differences in how these two groups handle aspects such as security and privacy and it is critical to make sure you are using the appropriate devices in the right way.

Is IoT new?

No, IoT (or connecting items to a network so you can remotely monitor, operate, manage them) has been around for a very long time in industrial settings. Things like SCADA and PLC systems have been managing utility networks effectively for many years.

What has changed though is technology advancements having an impact on the capability and cost of the building blocks of IoT we mentioned earlier (devices, connectivity networks and platforms).

Over the last two decades, the telecommunication industry has made great strides in providing a raft of new and better connectivity options. From BLE (Bluetooth), LoRa, UWB (Ultra Wideband), Sigfox and all the flavours of “G” (2G, 3G, 4G, 5G…) including NB-IoT and Cat-M1 to satellite systems, there are more ways to connect things, in real-time, than ever before. This has meant there are better solutions and economics at play making more business cases work.

This connectivity flexibility has spawned thousands of new devices that can easily be attached to items or integrated into the manufacturing process when an item is built. Production processes now make it easier to make smaller and customisable devices, with longer battery life and better performance. This has also helped scale production which again has helped lower costs making more business cases work.

The last piece of the puzzle is having a platform that can take in (ingest) data from all these different devices and networks, process, analyse, visualise and distribute that information to the people and systems (like CRMs or ERPs) that will benefit from it. Again, technology developments have made building scalable platforms possible and easily able to work globally. Platforms like Perspio™ perform this important function and as a software as a service solution, the costs associated with getting started are much lower, again helping business cases work and making sure there is real value generated quickly.

Why should I care about IoT?

If you take an industry such as agriculture, measurement tool manufacturers have been racing to build the most precise measurement systems – which has led to very good but very expensive point of time and place data measurement capabilities. This also requires, more often than not, human operation.

IoT devices may be less precise by themselves, but they can help ‘connect’ existing sensors or help increase the number of sampling points, providing a better understanding of the model than a single geographical point. This is very true for everything around soil management for example to make the best irrigation or fertilizer application decisions.

Industrial IoT then is truly realised when you have many monitoring points providing a much more accurate representation of the behaviour of assets and machinery and the environment in which they operate, giving you the ability to make these assets more efficient.

Why should I launch into IoT?

Well, the answer to this is simple: if it doesn’t make you more money (increased revenue or cost savings), make you more compliant, or create a better customer experience, then you probably shouldn’t. In most cases however, you will find that you fit in one of these categories:

- I’m not sure my assets are being utilised to maximum efficiency, maybe I have too much/too many or not enough capability. Maybe my assets aren’t always in the place I need them. Fixing these issues makes you more money.

- I don’t have good visibility into my operation in real-time. What’s going on? Where are my people, are they compliant (training/safety), where are my hazards/risks today? Is something happening right now in my factory or on my site or farm that I should know about so I can take action right away? Getting this visibility helps you make money and be more compliant.

- I’m too reactive to machinery/asset breakdowns. I lose time whenever that happens. What if I were able to predict potential failures and therefore increase my uptime? Fixing this will make money and provide better customer experience.

But as you can expect reading through these examples, it’s not just about enabling telemetry on an asset (this needs to be done for sure) but really using the data coming out of it to understand what is happening and being able to make the decision to do something about it in the context of the operation. That’s where you truly generate value – until then, you’re looking at dots on a map.