Challenge:

Typically, asset owners maintain their equipment on a regular, time-based or distance-based schedule.

In equipment hire, lack of visibility means you have to service your equipment whenever it gets back to the yard, or when customers tell you that it has reached a milestone.

This is both inefficient and a major risk, especially when you have to manage equipment warranties,

which is exacerbated when talking about long-term hiring. You also have no visibility on your customer’s pre-starts.

Risk:

Without knowing how your equipment is being used, you are at risk of either under-servicing – your

equipment might break – or over-servicing. You’re also putting your supplier warranties in jeopardy by not being able to prove the equipment has been adequately serviced.

Either way, that translates to costs that you don’t want to have on the books.

Solution:

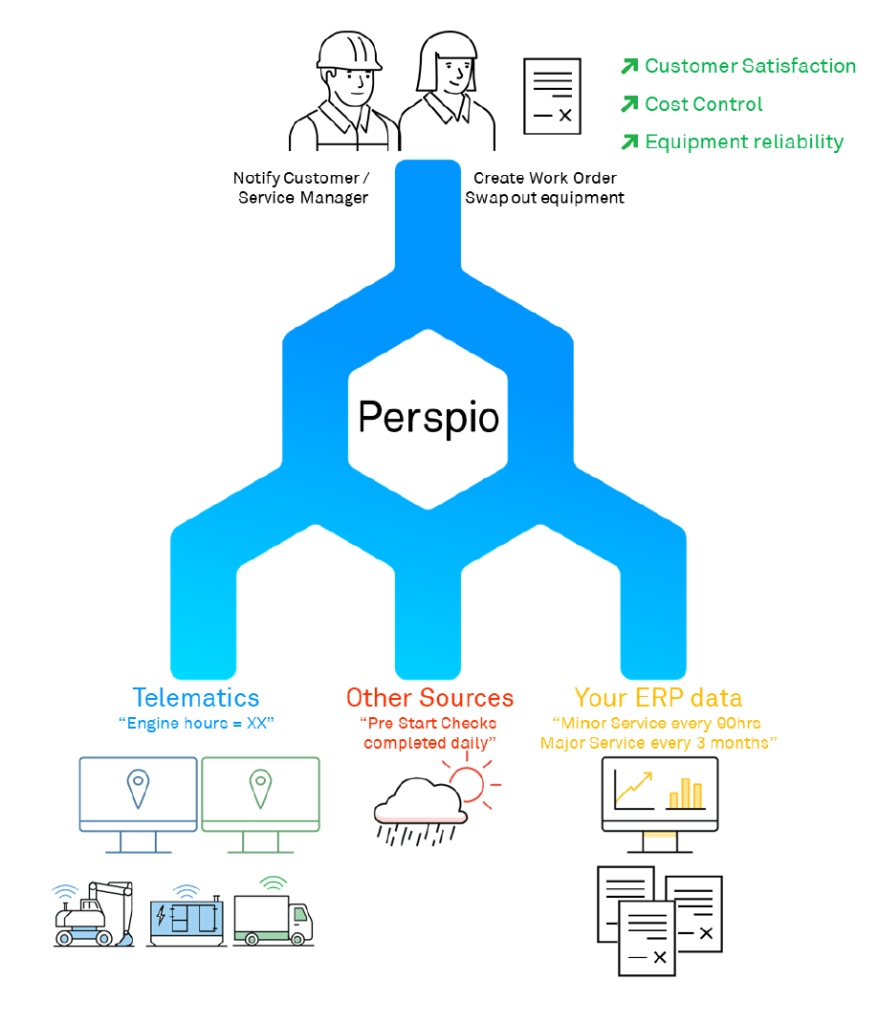

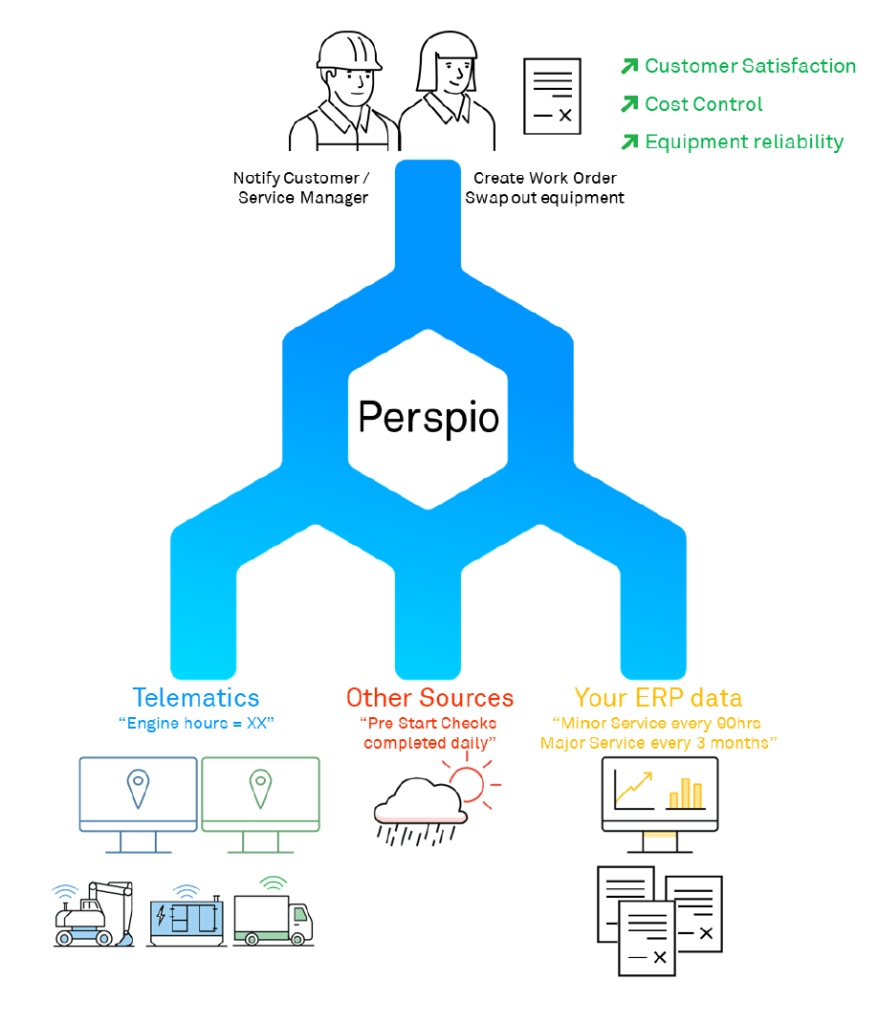

By being able to analyse the telemetry data, which offers a real-time view of asset utilisation, and compare it to the servicing schedules from your service management dashboards, our platform can predict an asset’s remaining lifespan.

Depending on the telemetry you have, we can also start identifying any abnormal machine behaviour, and automatically trigger a suitable corrective action – whether the creation of a prefilled work order to a field technician, or the replacement of the asset on the contract and the creation of a transport docket.

The servicing data can also be automatically flown back up to your suppliers ensuring any warranty claims can be dealt with swiftly.

Completed pre-starts can also be registered, making it easy for you to know which customers are taking the best care of your equipment.

This means you can say goodbye to manual equipment checks and maintenance schedules.

Enjoy more uptime, less cost, and increased customer satisfaction.

Are you ready to #getyourdatatowork? Reach out to the team!