Digging up data to ensure your earthmoving business is safe, efficient and profitable shouldn’t be difficult. But when it comes to choosing the right telemetry solutions, it can sometimes seem a mountainous task.

Telemetry plays a significant role in enhancing the earthmoving industry’s efficiency, safety and overall performance. Today, we’re unearthing the different telemetry solutions for earthmoving businesses and exploring how they can help you improve your operations.

How to choose the right telemetry in earthworks

There are three primary considerations when choosing telemetry solutions in the earthmoving industry:

- What data do you need to ensure governance, safety and maintenance?

- What data would you like to optimise operations and profitability?

- What’s your investment?

Once you’ve covered these questions, it’s a matter of finding a product that suits your equipment and operational needs. Some businesses will benefit from a simple solution, while others will see a greater return on investment (ROI) with a comprehensive approach.

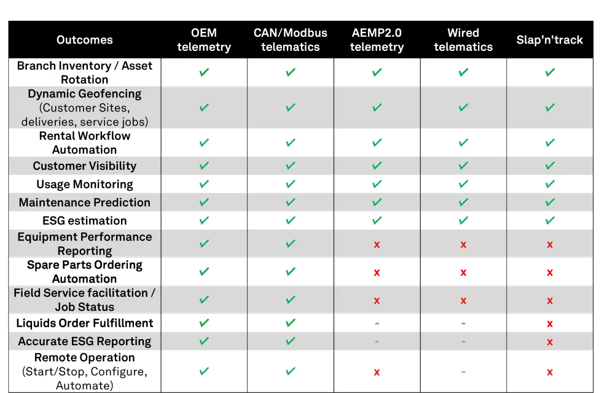

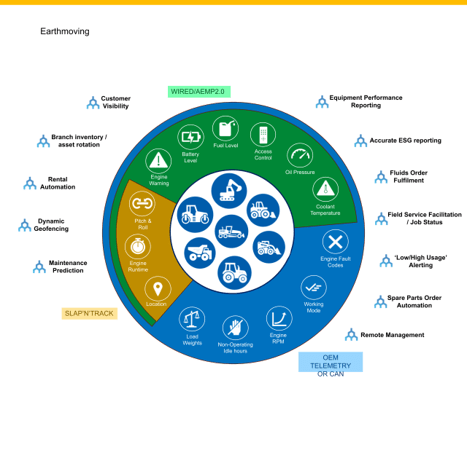

The different types of telemetry solutions

Original Equipment Manufacturer (OEM)

OEM refers to telemetry solutions embedded within the machinery by the manufacturer. You’ll likely find this telemetry in recent earthworks equipment designed for commercial use over a certain value. This is generally the most complete dataset you would be able to get to.

Controller Area Network (CAN)

CAN/Modbus telemetry solutions are known for their compatibility with a wide range of equipment and machinery, making them suitable for use across diverse earthmoving fleets. CAN telematics will provide some level of fault codes, based on mappings maintained by the telemetry provider.

AEMP2.0

AEMP2.0 is a form of standardised data format, facilitating consistency and interoperability across different types and brands of equipment. There are variations within AEMP2.0, although a number of data fields are common.

Wired Telematics

Wired telematics systems provide data by cabling directly into the electrical wiring of the asset, ensuring highly reliable life expectancy, whilst providing simple data points like levels of liquids or engine lights.

Slap ‘n’ Track

As the name suggests, Slap ‘n’ Track telemetry is a simple, cost-effective and easily removable solution that helps you monitor earthworks asset tracking.

Identifying your business needs

Any equipment delays on a job site can have a significant impact on stakeholders. Failure to keep your earthmoving equipment maintained and safe can harm your brand and reputation (not to mention the financial loss).

Here are some of the most common benefits to consider for telemetry in earthworks and the solution we’d recommend:

- Equipment Monitoring and Diagnostics: Monitor engine performance, fuel consumption, temperature and hydraulic system health in real time. This helps identify potential issues before they lead to major breakdowns, reducing downtime and maintenance costs.

We recommend: OEM or CAN.

- Fuel Management: Earthmoving equipment often consumes large amounts of fuel. Telemetry solutions can provide insights into fuel consumption patterns, helping operators and fleet managers optimise fuel usage, reduce costs and minimise environmental impact.

We recommend: OEM, CAN, AEMP2.0 or Wired.

- Maintenance Planning: Maintenance planning enables predictive maintenance by collecting and analysing equipment health and performance data. This lets you schedule maintenance activities based on actual usage and condition rather than fixed time intervals, optimising the lifespan of components and reducing unexpected failures.

We recommend: Any, although Slap’n’track may have some inaccuracies with regards to Engine hour detections

- Operational Efficiency: Get real time information on the location and utilisation of equipment. Fleet managers can optimise equipment deployment, route planning and task allocation, increasing operational efficiency and productivity.

We recommend: OEM, CAN or Modbus for comprehensive data, but if you’re after simple usage monitoring, choose AEMP2.0, Wired or Slap ‘n’ Track.

- Safety Monitoring: Monitor and enforce safety protocols by tracking equipment speed, usage in restricted areas and operator behaviour. This enhances overall job site safety and reduces the risk of accidents.

We recommend: Any.

- Asset Tracking: Earthmoving equipment is often spread across large construction sites. Telemetry solutions enable accurate asset tracking, helping companies keep tabs on the location of their equipment. This can deter theft and aid in recovery if equipment is stolen.

We recommend: OEM, CAN, Modbus, AEMP2.0, Wired or Slap ‘n’ Track.

- Data Analytics and Reporting: Generate a wealth of data you can analyse to gain insights into equipment performance, operator behaviour and job site efficiency. This data-driven approach allows for informed decision-making and process improvements.

We recommend: Any, however, insights will be limited to the data available.

- Remote Equipment Immobilisation: Securely immobilise your machinery remotely. This can be especially useful in challenging or hazardous environments.

We recommend: OEM, CAN or Wired.

- Environmental Impact: Minimise your environmental footprint by optimising fuel consumption, reducing emissions and ensuring efficient use of resources.

We recommend: OEM, CAN or Wired.

There are different telemetry solutions available for earthmoving businesses. The solution depends on what you need to make your day-to-day operations run smoothly.

ESG considerations for the earthmoving industry

The adoption of telemetry in earthworks also has the potential to positively impact your Environmental, Social and Governance (ESG) factors. Construction machinery monitoring can help you promote environmental sustainability, enhance social wellbeing, demonstrate good governance practices, improve operational efficiency and showcase a commitment to technological innovation. Companies that prioritise these considerations are likely to be viewed more favourably by investors, customers and other stakeholders in the context of ESG criteria.

There are also financial benefits to gain from proper fleet maintenance, quality control and the ability to plan for the future. Having historical records on file allows you to negotiate new tender applications and identify the performance of your current fleet. This analysis is also helpful when applying for fuel tax credit (FTC) rebates. With Perspio, you have the capability to accurately report on FTC and streamline the management of these claims, ensuring a thorough and efficient process.

Max Girault, Inauro’s Chief Commercial Officer, also weighs in on the importance of telemetry in earthworks to reduce fraud, stating, “Transparency across your earthmoving business provides a lens to improve efficiency and operations. We recently worked on a case to query the operator hours versus asset hours for a client. The earthmoving machinery was hired from one company, and the labourer was provided by a second. We found twice as many hours lodged by the labourer than were actually recorded by the Perspio™ telemetry solution. This resulted in a very quick resolution for our client and a considerable cost saving. This is just one of the many examples we’ve seen where companies have the data they need to support their team and their equipment.”

Future-proofing your telemetry solutions in earthmoving

A data fusion operational IoT platform like Perspio™ is key to providing additional context across any telemetry solution and operational system to help you analyse and improve your operation. The platform is uniquely designed to adapt to existing solutions, offering users control over theming, role-based access, feature activation and consumption levels. As a fully flexible and modular solution, Perspio™ can seamlessly communicate with various earthmoving assets, platforms, devices and data sources, adjusting its level of integration as needed.

If you’re interested in hearing more about the best telemetry solutions for your earthmoving business, reach out to the Inauro team for expert advice.